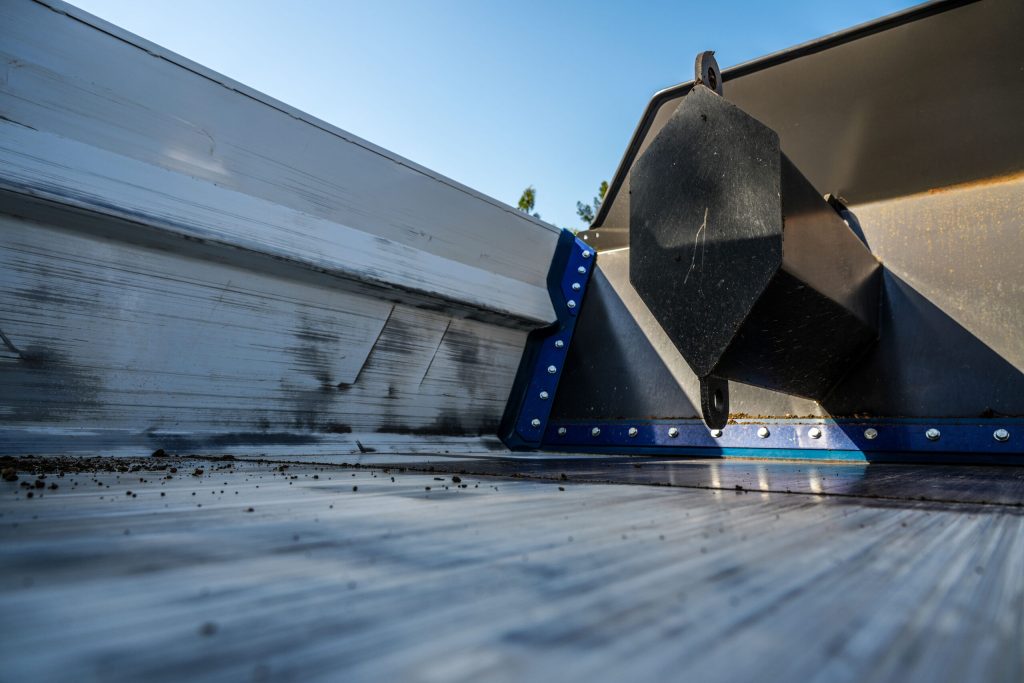

Discover EjectX

The EjectX allows you to move your material without the safety concerns of a tipper and without the limitations or cleaning of a live bottom truck.

LEARN MOREUsing a horizontal hydraulic ram to push material through the body as the tailgate automatically lifts – all while the truck and body remain in a stable and horizontal position allowing you to efficiently eject your payload right where you need it and exactly how you want it every time, regardless of your surroundings.