EjectX

Australian made ejector truck body

EJECTX IN OPERATION

EJECTX FEATURES

When Safety Matters

Australian-Made Ejector Truck Body

The EjectX was designed due to a need for a safer alternative to tipping bodies, while increasing productivity. The EjectX is a heavy-duty, light weight body that is built for all solid material.

how the ejectx works

The EjectX body allows you to move your material without the safety concerns of a tipper. Using a horizontal hydraulic ram to push material through the body as the tailgate automatically lifts -all while the truck and body remain in a stable and horizontal position, allowing you to efficiently deposit your payload right where you need it, and exactly how you want it, every time, regardless of your surroundings.

BUILT TUFF

Our design incorporates a purpose built, double bushed, horizontal hydraulic ram that pushes a plough through the Bisalloy body, ejecting the material you load in the back.

The tailgate automatically lifts, then the plough moves through the body at either a set speed or inched through for part load ejection, which allows your material to flow freely out of the body. This reduces any wear and tear on your tailgate.

These bodies will push anything solid from profiling’s, demolition materials, rock and rubble, right through to hot or cold asphalt.

INCREASING SITE SAFETY

Designed and built with safety as the main priority, the EjectX is safe and user friendly, reducing risk of damage to your equipment and increasing safety on site.

Increased safety is achieved with included features such as, a system where the plough cannot move unless the tailgate is released. You also don’t have the safety concerns that accompany conventional tipper bodies.

The EjectX comes standard with an in-cab control panel to operate the entire system from the comfort of your driver’s seat. The in-cab control panel not only provides the ability to control all functions and operations while viewing your body in real time, but it reduces operator error with the preloaded modes.

The control panel provides valuable information such as hydraulic oil temperature, camera views of your load and rear of your body, as well as live updates of the body status at any time, including plough location, tarp position, tailgate position and lock status. Just to name a few.

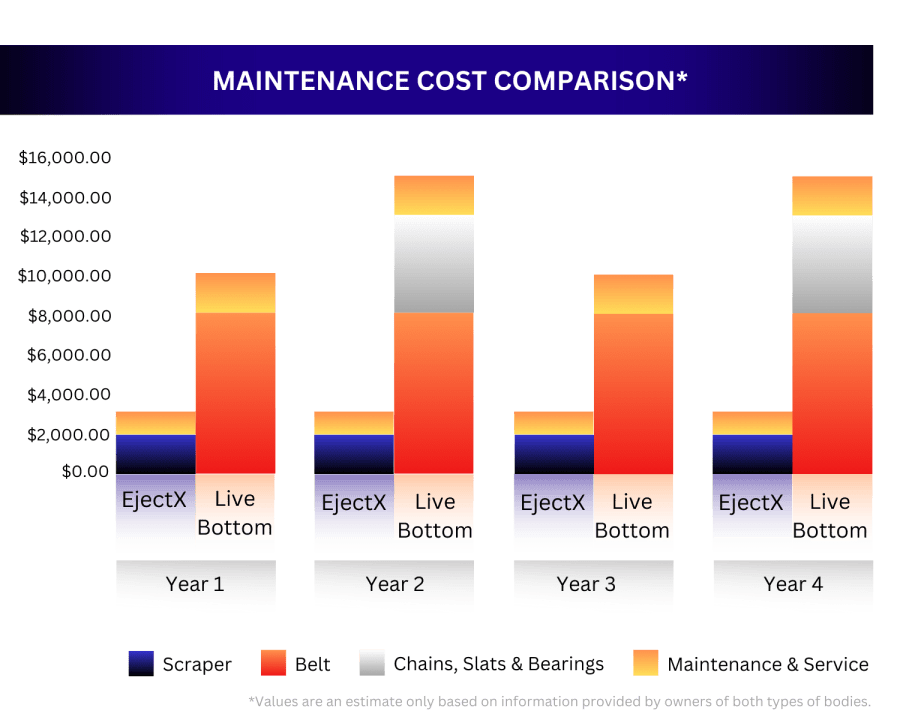

THE MAINTENANCE

The ejection system installed is a low maintenance system with no chains, slats, belts, bearings or hydraulic motors, reducing the amount to go wrong. The EjectX is a simple system ensuring your maintenance costs and downtime are minimal.

BENEFITS OVER LIVE BOTTOM TRAILERS

- Clean body after unloading

- No restriction of material type -Suitable for all solid material

- Low repairs & maintenance costs and downtime

- Reduced operating costs with less body clean out

- No cross-contamination of material

- Low centre of gravity

- Low side height for loading with a Bobcat -for clean up jobs

- No belts, chains, slats or bearings causing costly repairs

- Less obtrusive parts to be hit & damaged

- Ability to eject sticky and cold asphalt

- Controlled material displacement

Benefits over tipping bodies

- No tipping

- Reduced operating costs and cycle times

- Reduced operator error

- Greater operating range with the ability to eject on adverse slopes

- Reduced roll over risk

- Eliminates carry-back due to specifically designed scrapers on the plough

- Controlled material displacement

- Easy to operate

- Low centre of gravity

- Allowed on all job sites in Australia

- Safer near powerlines, low hanging trees and obstructions